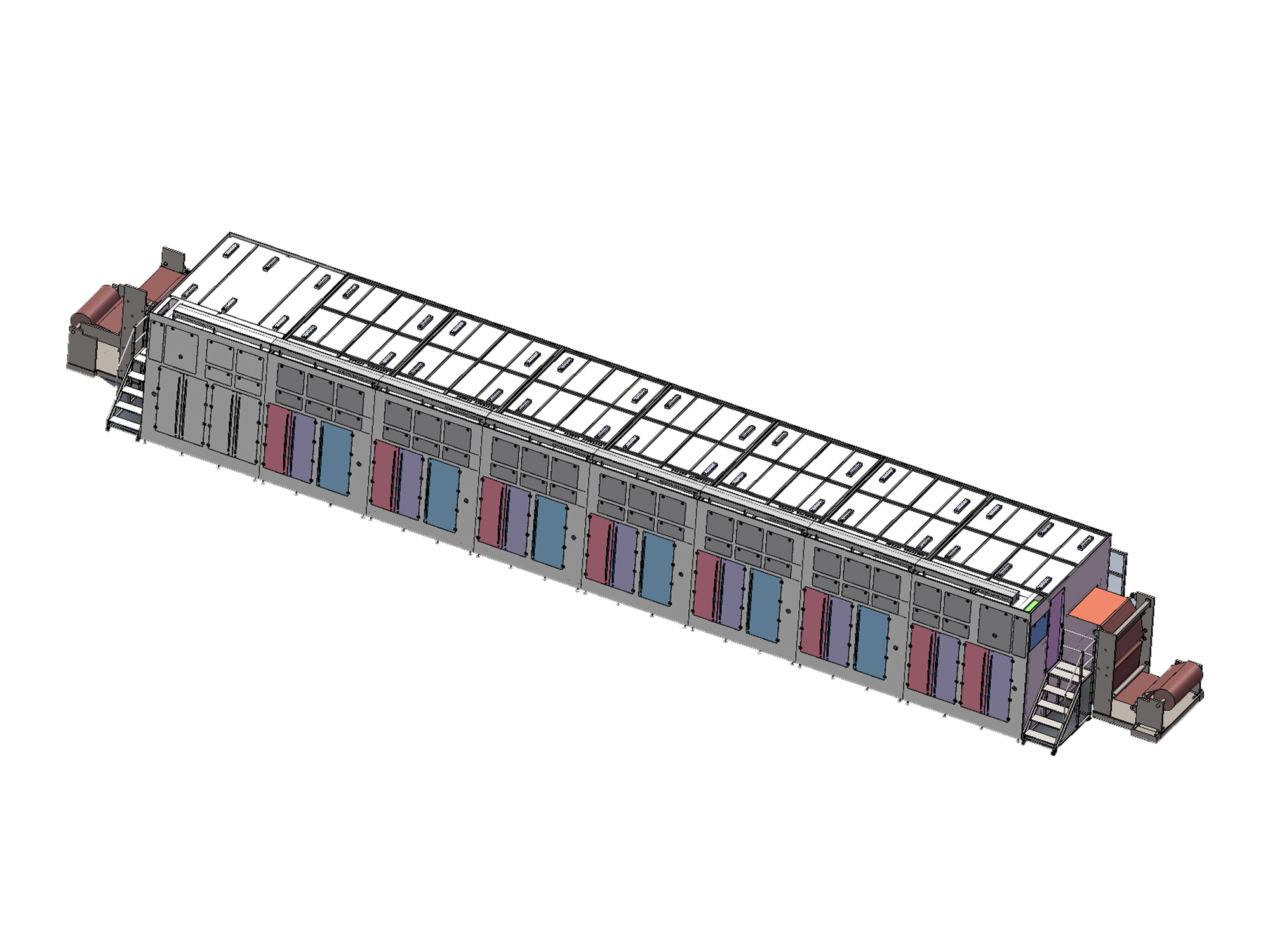

Horizontal roll-to-roll plating cleaning equipment

Horizontal roll-to-roll plating cleaning equipment

Features

·RTR vertical "U" -shaped full immersion, no pool effect.

·Low-tension control system, reducing film stretching deformation, zero tension in the plating bath section.

·The patented anode spray box, combined with inert DSA insoluble segmented anodes, enables rapid replacement of chemicals.

·Reduce the usage of bath chemicals and wastewater.

·0.5-4ASD high current density, shortening electroplating time.

·The life cycle of electrolytes is longer.

·The anode has a longer lifespan.

·Automatically adjust the electroplating parameters and curve graph, and the rectifier to achieve a constant current density. Small-batch and multi-batch types running simultaneously.

·The sealed electroplating chamber cavity reduces ventilation efficiency by up to 90% and minimizes heating loss. It has greatly reduced the electricity cost.

·The extremely low material resistance at the inlet and outlet of the immersion tank seals the liquid water gates to reduce the amount of carryout and waste treatment, water consumption and chemical uses. Based on the design, the risk of leaving marks or damaging the material is eliminated.

·Horizontal and vertical "U" electroplating reduces the risk of copper particle adhesion on the surface and increases the yield.